Vacuum & refrigeration

High-efficiency compressors and oil-free vacuum options deliver fast pull-down and stable, repeatable cycles.

- Oil-free or low-maintenance vacuum pumps

- Optimized condenser/trap capacity

- Quiet, energy-efficient operation

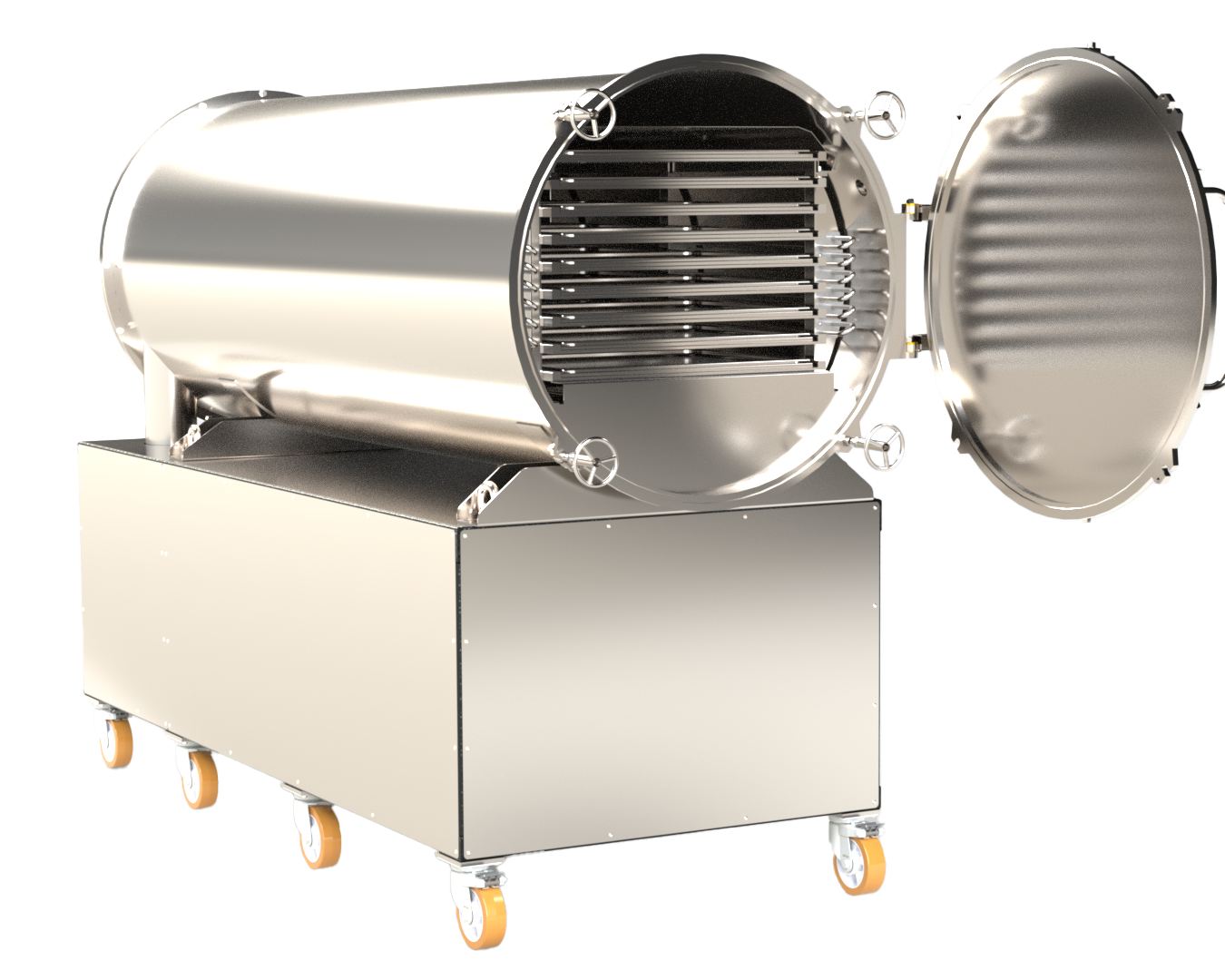

We understand the needs of food processing industry. Basing on our expertise, we thrive to provide you with efficient, durable and safe equipment that you can rely on in your everyday activity

We understand the needs of food processing industry. Basing on our expertise, we thrive to provide you with efficient, durable and safe equipment that you can rely on in your everyday activity

| Leosmak | Competition |

|---|---|

| Stainless steel chamber | Often not stainless steel (only optional) |

| No electronic components inside of the chamber (fully washable interior) | Electronic components inside of a chamber, problems with HACCP compliance |

| Eco-friendly refrigerants (EU compliant) | High GWP, some banned in EU |

| Broad functionality of the device | Limited functionality only |

| 24-month warranty | Typically 12 months |

| Advanced Iot integration | Limited IoT features |

High-efficiency compressors and oil-free vacuum options deliver fast pull-down and stable, repeatable cycles.

Industrial-grade electronics and sensors with safe wiring, documented for QA and serviceability.

.png)

Food-grade elastomers and smooth finishes prevent buildup and enable quick wash-downs.

.png)

Rigid, corrosion-resistant racks and trays ensure even drying and easy handling.

In the modern food industry, the demand for innovative, healthy and sustainable methods of food preservation and processing is growing faster than ever. Consumers expect natural taste, long shelf life, and nutritional value — all achieved without artificial additives.

At Leosmak, we design and manufacture advanced industrial machines that help food producers meet these expectations. Our portfolio includes freeze dryers, vacuum dryers, shock freezers and customized process solutions that ensure top quality, safety, and efficiency at every stage of production. By combining engineering precision with deep understanding of food technology, we support companies in adapting to the future of food processing — where innovation, quality and responsibility go hand in hand. Our equipment is designed to meet the highest food industry and sanitary standards, helping our clients grow in line with modern consumer trends and global sustainability goals.

Freeze-dried food market forecast (2034)

approximate price of freeze dried food in Europe

weight of lyophilized product compared to original food, with the same nutritional value

approximate shelf life of freeze dried food with advanced packaging

We focused on quality and sustainable development and you can really feel the power od precise enginering which has been used in every single unit we put on the market.

Each model we manufacture is equipped with CE declaration of conformity which confirms compliance with following directives and regulations:

We can operate for long time in food service system and we have knowledge about preparation, handling from each type of product and what is best for your business.

Although we are young company, we have already started the process of certification of Quality Management System under ISO 9001:2018, which we expect to be finished in 2025. Feel free to contact us should you have any suggestion about the quality of products and solutions we provide.

We are a team of professionals with proven track record in multiple projects. We have studied and gained experience all over the world, focused on excellence and quality. These were the main reasons our headquarter and production promises we formed. Our team consists of engineers, installers, project managers, software developers and client supporters fighting to provide best solutions for our clients.